As the severity of the corona virus pandemic forced Malaysia to go into Movement Control Order (MCO) on March 18, people were asked to play their part by staying at home to help contain the spread. A couple of Intel employees in Penang decided to do more than just stay at home to play their part.

In Penang, Loh Wei Keat, ATTD Malaysia site manager and David Ting, APJ Inside Sales field application engineer, recognized the need to help the healthcare front liners in the government hospitals who were dealing with the shortage of masks while handling COVID-19 patients.

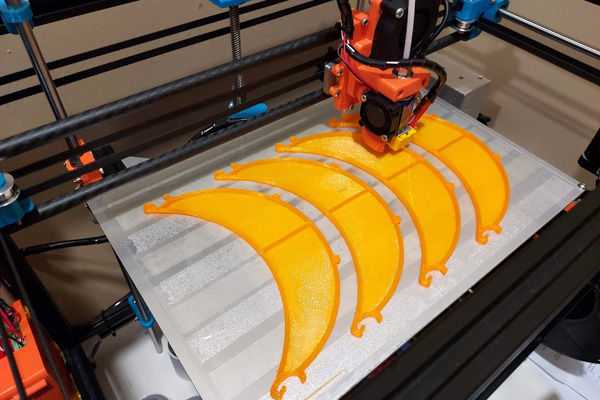

The duo shared notes and sourced design blueprints from the local maker community to print face shields on their personal 3D printers. Both Wei Keat and David have been able to 3D print around 40 to 50 protective face shields per day using their 3D printers at home.

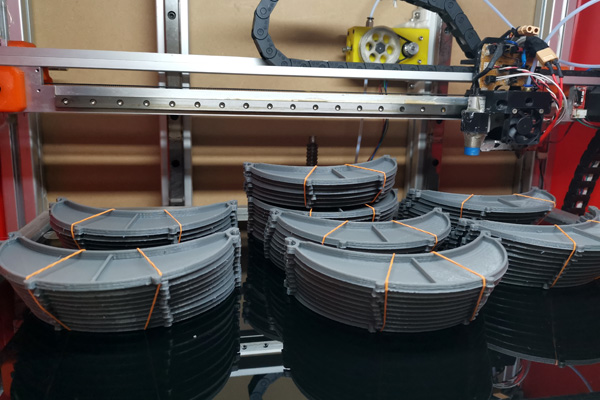

So far, they have handed over close to 500 face shields to the Penang Science Cluster (PSC), a science-first non-profit that works in tandem with the Penang government and the local hospital network, ensuring these much needed Personal Protective Equipment (PPE) items will reach front line hospital workers.

The PSC takes the masks and sterilises them before other volunteers attach plastic shields and elastic bands to the 3D-printed parts.

Wei Keat says the 3D-printed shields have a distinct advantage over existing commercial designs. “The 3D-printed frame can be sterilised and reused, which reduces waste. And it’s also cheaper and relatively less complicated to use, versus the foam types,” he said.

Each piece takes anywhere from 22 minutes to an hour to 3D print and the printers require constant attention to instantly identify and fix a variety of issues that can arise during the printing process.

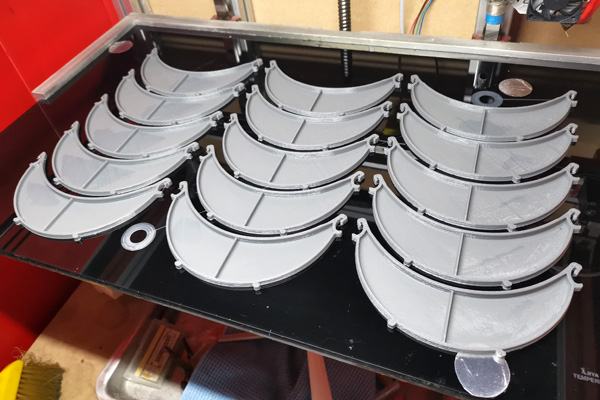

In typical Intel fashion, both David and Wei Keat are already looking for ways to improve on their design, based on real-time input from the maker community, and real-world feedback from doctors in the field. “Today, we came up with the first revision of the face shields, and we’re sharing that with the doctors and medical teams for evaluation,” Wei Keat revealed.

David shared. “We’re keen to do our part to help and we knew it was the right thing to do. We’re reaching out to more makers across the Intel community, and we’ll hopefully be able to increase the volume we’re delivering to the medical community.”

At the corporate level, Intel Malaysia recently committed to donate over RM2 Million to purchase test kits, ventilators, patient monitors and air purifiers for General Hospitals in Penang and Kedah and provide support for other Malaysian Government agencies via the American Malaysian Chamber of Commerce’s #MYAMCHAMCares program. Part of this RM2 million is being donated to PSC to enable the move to high volume injection moulding that will help them make 2000 face shields a day to be provided free to all 6 General Hospitals and 40 medical clinics in Penang and other northern states as well.